How to size an air compressor for sandblasting

Ever wondered what sandblasting is all about? How it works and what it’s used for? If you have, this blog will address everything you need to know about sandblasting as a whole.

According to historians, it is believed that sandblasting was first patented after the observation of what appeared to be sand-laden winds. Apparently, this seemed to significantly affect objects or surfaces they met. This observation was made by none other than Benjamin Chew Tilghman – the person who invented the first air compressor.

Sandblasting is also known as abrasive blasting. It is the operation of forcibly propelling a stream of abrasive materials against a surface. It is done under high-pressure to smooth out a rough surface, roughen a smooth surface or shape the same to remove its contaminants.

The abrasive material for this operation is chosen based on the finish required on the surface.

To get the best performance from your sandblaster, you need to select the right compressor for the job.

Choosing your compressor:

Compressors and sandblasters are sized based on:

- Flow: Defined as the volume of air that the system can move in a minute, the flow is dictated by

- Number of users

- Hose length

- Hose diameter

- Nozzle size and type

- Pressure: The pressure generated by the system is dictated by media, hose length, & diameter

One must consider both numbers to make sure the compressor and sandblaster will work together. The size of the sandblaster and nozzle will determine what size of the compressor should be used for the operation.

How sandblasters work:

To select the right size of the compressor for the operation; it is necessary to understand how exactly a sandblaster works. They clean out rough surfaces by abrading them with sand that is fired out of an air-powered gun at high velocity.

- Different types of projection systems that can throw abrasive using compressed air:

In pressurised projection systems, both abrasive pot and air mixing champers are under the same pressure, sweeping the abrasive material along in the blast hose. - In suction systems, compressed air is injected into the gun through a nozzle which creates a partial vacuum that sucks a mix of air and abrasive materials from the pot.

- In gravity systems, the abrasive material enters the mixing chamber by gravity and is then pushed by compressed air into the nozzle.

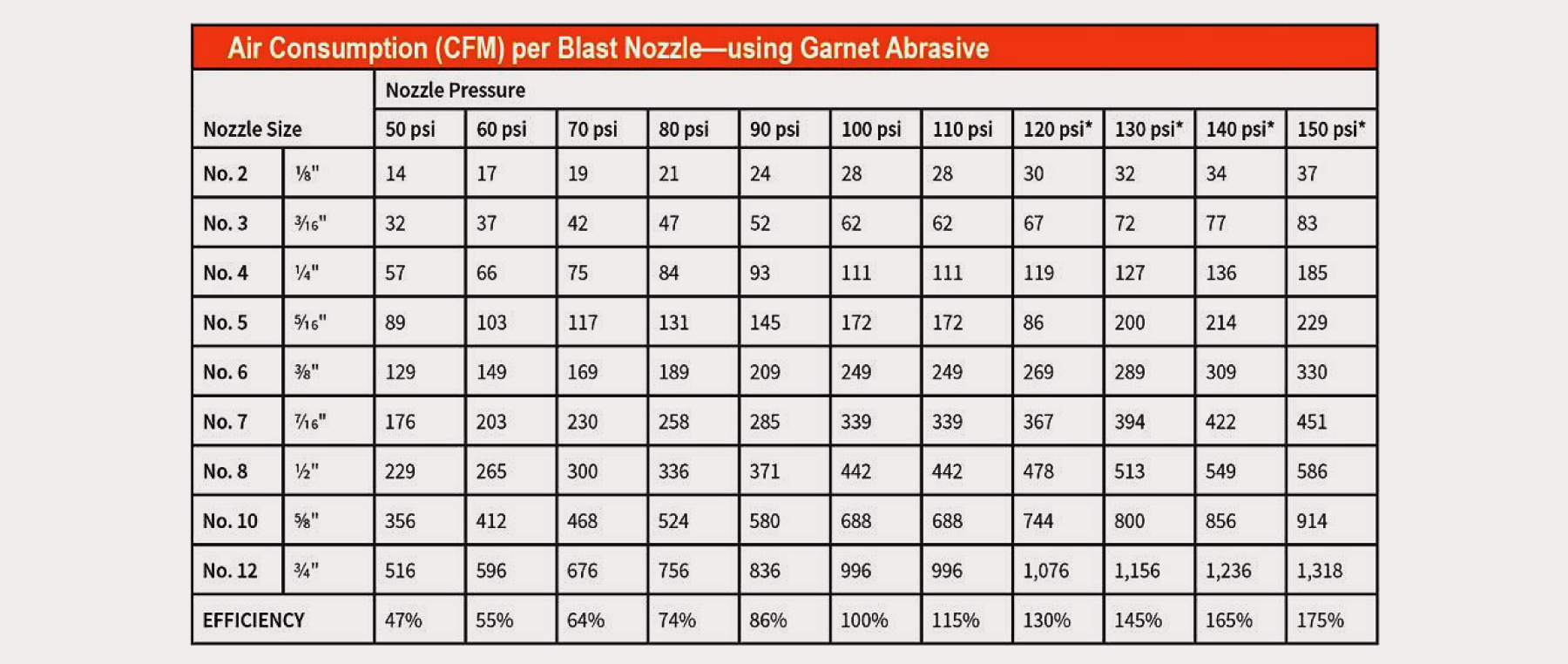

Nozzle Chart – Air Consumption:

Air and Abrasive consumption per blast nozzle

There are many factors to consider when you’re sandblasting. Do check the guidelines of your sandblaster to make sure it’s compatible with your nozzle. You will also require a nozzle that is durable enough to withstand the pressure from your chosen sandblaster. After that, please check the PSI and CFM levels of your sandblaster and increase the size of your compressor accordingly in line with other equipment.

With the right compressor, you can power any sandblasting project efficiently. To know more about the compressors suited for sandblasting applications, visit here.