Compressed Air Dew Point – Why is it so important & How to Measure it?

Compressed air plays an important role in multiple areas of manufacturing including food, machineries, automotive and pharmaceuticals. It is an excellent source of energy used for conveying liquids, materials, to operate tools and equipment along with instruments.

During the compression process, ‘Dew Point’ plays an important role in maintaining the quality of the output or the product. Read on to find out more about this concept, and its impact on overall product outcomes.

What is Dew Point?

Dew point is the temperature at which the water vapour within the air condenses into dew or frost. Pressure Dew Point (PDP) is the temperature at which the water vapour in the compressed air condenses into water.

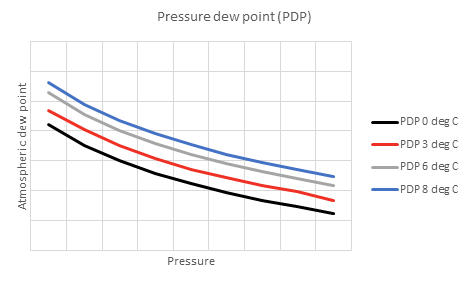

The atmospheric dew point temperature varies for air at different pressures. For eg. Considering the PDP 3 Deg. C line in the below generic graph, the atmospheric dew point temperature decreases as the pressure increases.

In a refrigerated air dryer, the compressed air is cooled to a temperature to remove the moisture content in the air. The volume of moisture that will condense from the air will be based on the pressure and the Relative Humidity (RH) compared to Atmospheric dew point.

Why is it important to maintain the Pressure Dew Point?

If the compressed air is not treated for moisture content it is going to corrode the pipelines, affecting the life of seals and other components.

- To reduce maintenance costs – improve the life of the compressed air components, thereby increasing the maintenance interval and improved function of the equipment and finally overall product quality.

- Reduces the downtime – re-work on the pipeline involves a huge task, extra manpower, safety concerns and the major consequence is of the production getting affected.

Hence, it is important to understand the basic and specific requirements of the moisture content for the compressed air system and application point.

For eg. The minimum requirement of a compressed air for a pipeline application is 3 °C PDP.

How to measure the Dew Point?

The dew point is measured using an instrument called Hygrometer. Installing the device helps us to monitor the moisture levels in the compressed air and take measures to maintain the dew point at the desired level by adding suitable air treatment accessories in the compressed air system. It will also help us to assess the performance of the air treatment equipment and understand its maintenance interval.

Quality standard: ISO 8573

Compressed air consists of particles, water vapour, and oil content. However, for us to maintain quality in product and process, the compressed air must meet the ISO 8573 industry standards.

ISO 8573 - Compressed air purity classes for humidity and liquid water

|

Pressure dew point |

||

|

Class |

oC |

oF |

|

1 |

≤ -70 |

≤ -94 |

|

2 |

≤ -40 |

≤ -40 |

|

3 |

≤ -20 |

≤ -4 |

|

4 |

≤ +3 |

≤ +37 |

|

5 |

≤ +7 |

≤ +45 |

|

6 |

≤ +10 |

≤ +50 |

Type of Dryers:

The need for the pressure dew point temperature ranges from -70°C PDP for special cases like the food and pharma industry. The desiccant dryers can absorb moisture and produce air with -40°C PDP. Refrigerant dryers have the capacity to treat the air to 3°C ~5°C pressure dew point. It is necessary to choose a suitable accessory to maintain the dew point for various applications like breathing, food- processing, instrument, power.

Selection of dryer using correction factors:

It is important to use the correction factor table while selecting any type of dryer. By this method you can avoid higher sizing of the dryer which will increase the initial and running costs. Lower sizing of the dryer will result in not achieving the required dew point in the system. Selection of dryer using the correction factors will help to meet the application requirements.

Pro Tip: Adding additional accessories will improve the efficiency of the system.

For eg: Use of a wet receiver -> A Moisture Separator will reduce the load on the dryer, thereby increasing the efficiency of the dryer.

Another type of Refrigeration Dryer is a Cycling Dryer which has an extra thermal cooling medium that stores energy effectively and shuts down the refrigerant circuit to save power.