Improve the efficiency and effectiveness of your business with compressed air

Environmental, Social and Corporate Governance (ESG) is a framework within organizational strategy to generate value and safeguard interests of all stakeholders. It is an umbrella term which represents more than #30 trillion in assets under management.

Asset Managers and financial institutions are increasingly relying on ESG ratings to assess, measure and compare companies. At ELGi, our emphasis on Purpose has prompted us to embrace the Environment, Social, and Governance (ESG) approach to sustainable business with a primary focus on the environment, our people, and the community.

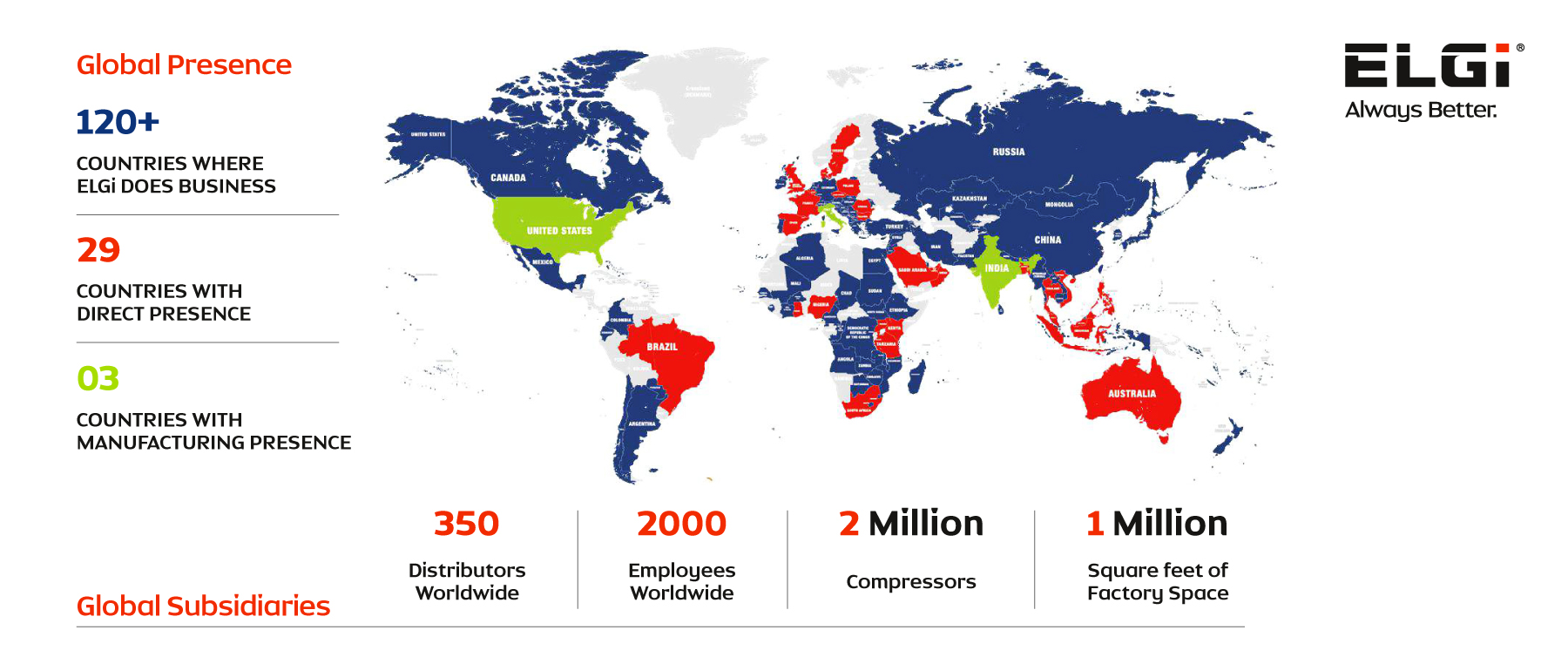

As an organization, committed for over 63 years to delivering world-class sustainable compressed air solutions. Our global footprint spans over 120+ countries, with state-of-the-art manufacturing facilities in India, Italy and the USA and a 400+ strong product portfolio.

We believe that to help our customers fulfill their ESG objectives, we must be a sustainable organization ourselves. We emphasize innovation to develop products that are energy efficient, aid in heat recovery and help reduce carbon emissions, enabling our customers to achieve lower life-cycle costs.

Where does compressed air fit in, in the ELGi Sustainability Roadmap?

Compressed air is so widely used that it is often regarded as the fourth utility, after electricity, natural gas and water. However, compressed air is more expensive than the other three utilities when evaluated on a per unit energy delivered basis –

- Air Compressors consume more than 10% of power in any Industrial set-up.

- Lubricated Air Compressors, globally, discharge more than 2Mn liters of oil into the environment each year.

- If not sized and managed properly, the overall efficiency of a typical compressed air system can be as low as 10%-15%.

- Leakage in the system contributes to as much as 20-30% of compressor’s output.

Hence, compressed air systems become an integral part of overall Energy management and in-turn ESG norms for any organization. Additionally, Governments and Customers across the world are becoming more and more energy cautious.

Further, customers should keep in mind that it is not just about the air compressor, but it is all about compressed air – hence the entire system encompassing Air Compressors - associated accessories, piping arrangement and control systems.

Type of compressor in operation, treatment of air in downstream side of compressor, condensate management, disposal of compressor oil, type of material used at part level – all of this impact overall system level efficiency and also have environmental impact.

Supporting customers with our ESG initiatives

- Accessories like Oil Water Separators are great solutions for managing compressor condensate onsite. They would also help customers with EHS regulatory compliance.

- The compression process generates lot of heat which is generally wasted. Keeping in mind the effects of global warming, it is imperative that customers use Heat Recovery options in their Compressed Air Systems. These systems can recover anywhere from 75-95% of heat generated by the compressor. It can be used for heating water or space heating. This would reduce overall power consumption for the customers.

- Air Audit is another powerful tool to access the leakage in compressed air systems and improve overall system efficiency. A comprehensive Air Audit will enable customers to identify ways to improve the performance and energy efficiency of their compressors.

These are among the few initiatives and/or recommendations that our customers can implement to improve the overall efficiency and effectiveness of their business with compressed air.

At ELGi, we are steadfast in our purpose of remaining #AlwaysBetter for the environment and ensuring our employees, customers, and the community benefit from a healthier, greener ecosystem.

Going forward, as organizations embark on their journey of ESG, compressor and compressed air systems will be one of the key elements. Customers should wisely choose their compressors and look beyond compressors to Compressed Air Systems.