Energy saving tips for your air compressor

Compressed air is critical to the smooth operation of plants and factories. Contributing to a great deal of convenience and efficiency, compromised compressed air can result in forced shutdowns, poor output, and significant costs.

It is a proven fact that about 70% of an air compressor’s lifetime cost comes from power consumption, which then increases your overall power consumption However, due to the effectiveness and capacity of production support extended by compressed air systems, that it is now an indispensable part of the factory setup, especially in the case of sensitive industries including healthcare, pharma, food & beverage, etc.

Many opportunities exist to reduce the energy used by compressed air systems, beginning with air assessment and air audit. Here are 10 expert tips to help you keep a tab on your electricity bill.

- LOWER THE PRESSURE: We all know that working under pressure can be hard. Every additional bar of pressure can increase your power consumption by 7%. Set your air compressor at the lowest possible pressure for a specific application. Remember that increasing pressure does not compensate for a pressure drop in the system caused due to leaks, faulty piping, or choked filters. Install a pressure regulator for better control. It’s also important to calibrate your pressure gauges at quarterly intervals.

- CHANGE FILTERS ON TIME: While replacing air filters, it is mandatory to maintain the quality of air, it is also an energy-saving opportunity. Delaying an air filter change may cost you a lot. Clogged filters can lead to pressure drops and also hamper efficiency. Ensure on-time service for a healthy compressed air system.

- INVEST IN PRE-FILTERS: Not only do pre-filters (also known as coalescing filters) help purify the air by removing oil and water, but they also help remove the particulate matter to a certain extent. Installing pre-filters for suctioning the air, and for its cooling, can extend the life of your compressor and its consumables.

- CLEAN UP: Besides keeping your air clean, ensure that you give your compressed air system a thorough dusting every few months. The presence of sludge, dust, or grime can have a big impact on the efficiency of the compressed air system. Pay special attention to compressor coolers and heat exchangers. Consider investing in a dedicated low-pressure air compressor, and airline for cleaning, to save power.

- PICK THE RIGHT DRYER: Selection of the right sized air dryer for your compressed air system is crucial. Make sure the energy consumption of the dryer is in proportion to the demand. An oversized dryer can add to your electricity bill significantly.

- CONSIDER A VFD: Screw compressors should run under full load. If the usage pattern varies, consider a Variable Frequency Drive (VFD) for up to 35% reduction in energy cost. A VFD helps regulate energy consumption based on demand fluctuations, ensuring energy efficiency. ELGi’s VFD has helped clients save up to 25% savings in maintenance and energy cost with payback as low as 7 months.

- PERFORM QUARTERLY MAINTENANCE CHECKS: The importance of maintenance cannot be overemphasized. Regular maintenance can help you identify and accurately measure leaks in the circuit. They also reduce the chances of breakdowns, leading to maximum uptime and productivity.

- PREVENT MISUSE OF AIR: Wasted air is wasted money. Invest time and money in training employees for efficient compressed air management. Create maintenance logs and update them on a regular basis and record abnormalities or leaks in the systems. Systematically label leaks with proper tagging and prioritize repairs and plugging of leaks.

- RECOVER HEAT It’s common knowledge that heat is produced during the process of air compression. If not used judiciously, all the heat energy can go to waste. Over 90% of the heat produced can be recovered and utilized for heating air or water at the facility.

- GET AN AIR AUDIT: Air audits enable companies to work with experts in the field and get valuable insights into their plant’s compressed air utilization. ELGi’s air audits chart out a customized and comprehensive energy management plan for your needs. Over the years, we have helped save millions of dollars in energy costs.

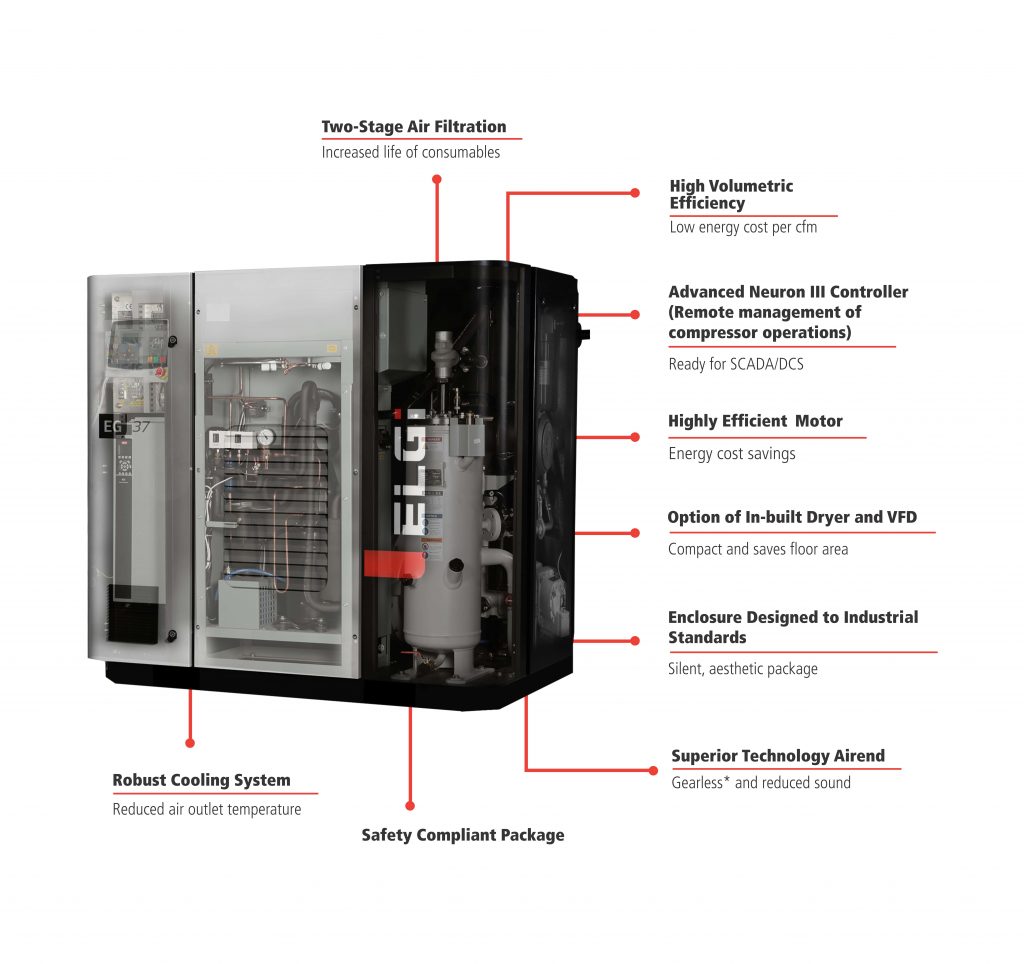

EG series air compressors from ELGi

EG Series, screw air compressor, is a highly reliable and energy-efficient series of air compressors. With multiple installations across 120+ countries and various industries, the EG Series has proven to be a reliable and dependable partner with its high uptime. EG Series rotary air compressor is also supported by an industry-leading warranty plan. Please check with your nearest ELGi representative for warranty plans available in your region.

With high performance and reduced energy costs, the EG series delivers consistent performance while ensuring maximum uptime and increased savings.

Want to know more about the EG series and its technology-edge? Speak to our air experts!