A 60-year partnership with the lifeline of the nation

The world's fourth-largest railway network, the Indian Railways, has always been the poster boy of scale and a veritable powerhouse of technology and infrastructure. With its diverse range of energy-efficient air compressors, ELGi is the largest supplier of air compressors to the Indian Railways for over 60 years, enabling the railways to lower energy spends and carbon emissions.

Paul Edward Theroux, the famous American novelist, and traveller, once said: "The railway possessed India and made her hugeness graspable." The Indian Railways is the world's largest passenger carrier and the fourth-largest freight carrier (1). It is the fourth-largest railway network globally-only behind the US, Russia, and China. (2) Its immensity can be gauged from the fact that the 95,981-kilometre route length of the Indian Railways carried 8.4 billion passengers and $1.2 billion worth of freight during 2018-2019. More than 12,000 passenger trains run across the country daily and cumulatively cover a distance more than four times the earth and the moon. (3)

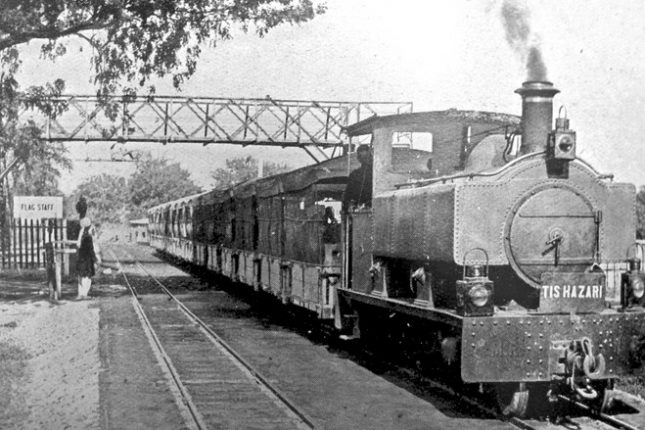

The Indian Railways began its journey in 1832 and has grown to become the giant it is today. As one of the primary drivers of India's economic growth, the Indian Railways has achieved this by being financially viable, technologically brilliant, and environment friendly.

The Indian Railways has also defied the trend that many big companies face.. On the contrary, they have cruised along and undertaken numerous initiatives to upgrade their infrastructure and quality of service..

These efforts have resulted in the Indian Railways achieving double-digit growth in freight traffic and doubling its freight speed on the back of massive infrastructural upgrades. Besides, new initiatives are always at play, from train control, signalling, and electrification to expansion through modern locomotives and EMUs, to name a few.

More importantly, the Indian Railways has its goals set with social and financial objectives in mind-from efficient energy use to the new decarbonisation paradigm and aiming to become a net-zero carbon-emitter by 2030. (7)

While all this is no mean feat as the world continues to struggle with partial lockdowns, there is a lot more to come, with India projected to account for 40% of the global share of rail activity by 2050. (4) The target is achievable since the government plans to invest ₹50000 billion in railway infrastructure by 2030. (5) It has also identified many new high-speed rail corridors besides planning INR 3 trillion worth of metro rail projects across various cities over the next five years. (6)

Addressing Challenges

For the Indian Railways, maintaining the highest standards of compressed air holds critical importance. Without it, machines unexpectedly break down, demand expensive repairs, or cause uncomfortable turbulence. For rolling stock of all capacities-from locomotives to good wagons to passenger coaches, whether powered by electricity or diesel – the railways need high-quality compressed air for smooth and safe operations. Moreover, various train components, whether the braking system, doors, pantograph devices, or air suspension, rely on high-quality compressed air solutions for safety and overall reliability. The Indian Railways is also subject to a variety of constantly changing compliances and regulations.

In the 1960s, the Indian Railways took many progressive steps towards modernization and adopted 25kv AC traction for electrification. (8) While the Indian Railways urgently required compressors to modernize the braking system, it could not directly import foreign solutions because the country was hit by twin mass famines (9), and liquidity was in short supply. Besides, though the second five-year plan (1956-61) initiated industrial import policies, there was not much clarity around it. (10) However, the government was proactively piloting several initiatives to trigger domestic economic growth. It encouraged the Indian Railways to initiate production work for electric locomotives at Chittaranjan Locomotive Works and flagged off the first 1500V DC electric locomotive from Bombay in 1961. (11)

By the early 1960s, ELGi began assembling and manufacturing small compressors under the brand name ELGi Uraca. It imported only major components and either manufactured the rest in-house or procured them locally. With urgent requirements arising from the Indian Railways, and a mandate to keep costs low, ELGi opened an indigenous compressor manufacturing unit in the heart of Coimbatore. The first product supplied to the Indian Railways was a 1000 litres per minute capacity compressor driven by a battery-operated direct current (DC) motor.

Since then, ELGi has consistently delivered a wide range of sustainable and efficient compressed air solutions to the Indian Railways. Today, 90% of Indian Railway's electric locomotives, 65% diesel locomotives, and 60% electric multiple units (EMUs) use ELGi air compressors for braking applications and auxiliary systems.

“The Indian Railways has been ELGi’s important customer for over five decades. Increasing urbanization and rising incomes have contributed to significant growth in the passenger segment, while freight traffic also saw a marked increase due to dedicated freight corridor investments. Our oil-free air compressors, renowned for reliability, performance, and energy efficiency, will revolutionize the way compressed air is used in the railway industry'' said Dr. Jairam Varadaraj, Managing Director, ELGi Equipments.

Picture credit - https://www.toprankers.com/exams/railway-development-in-india-1854-to-now/

Product innovation highlights: Creating value for the Indian Railways over decades

Continuous improvements and consistent focus on developing high-quality products have resulted in the design, development, and delivery of highly reliable air compressors that significantly reduce energy consumption and carbon emissions.

|

1965 |

Single-stage oil-lubricated DC motor-driven air compressor (CRC 150). With a smaller footprint and easy to mount on locomotives, this compressor efficiently lifted the pantograph. |

|

1967 |

Pneumatic air horns. |

|

1968 |

Two-stage air-cooled lubricated air compressor (TRC 1000 B) to blow horns, use windscreen wipers, and for efficient and safe braking in diesel shunting locomotives. |

|

1970 |

Pneumatic wipers. |

|

1979 |

Indigenously developed two-stage air-cooled lubricated air compressor (TRC 1000 WK) replaced the imported compressors for electric locomotives. |

|

1983 |

Water-raising apparatus (WRA-AC). These are lightweight, compact, and highly reliable for raising water from the underslung water reservoir in air-conditioned coaches. |

|

1986 |

Expressor (6CD 4UC) for diesel locomotives. The exhauster and the compressor combined into one unit form an Expressor. It creates a vacuum in the train pipe and air pressure in the reservoir for operating the brake system, air horns, and wipers. |

|

1990 |

Upgraded version of two-stage air-cooled lubricated air compressor (TRC 1000 MN) released for operating air brakes, air horns, and wipers in electric locomotives. ELGi successfully developed coach refrigeration compressors for air-conditioned coaches. |

|

1991 |

High capacity (2000 lpm) two-stage air-cooled lubricated air compressor (TRC 2000) for operating air brakes, air horns, and wipers in electric locomotives. |

|

1992 |

Expressor (6CD 3UC) for operating air brakes, air horns, and wipers in diesel locomotives with a high air compressor capacity of 200 cfm. |

|

1993 |

Two-stage lubricated DC motor-driven air compressor (TRC 1000 DCM) for electrical multiple units (EMU) with inline configuration. |

|

1995 |

Two-stage lubricated AC motor-driven air compressor (TRC 1000 ACM) for electrical multiple units (EMU) with inline configuration. |

|

1996 |

Pure air compressor (LG 3CDB) for diesel locomotives with a high air compressor capacity of 200 cfm. |

|

1999 |

High-quality, indigenous, and customized solution in the form of a 72 cfm/10.5 bar air compressor (TRC 2507) developed for the 1400 HP diesel shunting locomotives and diesel multiple units (DMU). |

|

2002 |

To develop a two-stage compressor for railway applications, ELGi set up a new plant measuring 30,000 sq. ft. with state-of-the-art equipment. A two-stage oil-lubricated, air-cooled, upgraded Expressor (RR 100101 EC) was developed for diesel locomotives with low maintenance costs. This acted as the upgraded version of the 6CD 3UC Expressor. |

|

2003 |

Designed and developed an oil-lubricated, air-cooled, underslung air compressor (RR 20100 CG (M)) to cater to the unique requirements of three-phase ABB locomotives, including high-speed trains like Rajdhani and Durondo. |

|

2005 |

ELGi developed a two-stage oil-lubricated, air-cooled new generation silent compressor (RR 15070) for Siemens MRVC coaches. These compressors were lightweight, without coupling with wire-rope isolators resulting in less vibration. |

|

2007 |

Upgraded version of pure air compressor (LG 3CDB). The two-stage oil-lubricated, air-cooled compressor (RR80101) with high reliability and low lifecycle cost enables operating air brakes, air horns, and wipers in diesel locomotives. |

|

2009 |

ELGi developed its first indigenous water-cooled air compressor (RR66101 W) for Indian Railways, meeting the requirements of the GM locomotives (WDP4 and WDG4) for DLW Varanasi. With this development, ELGi became the first Indian company to develop water-cooled compressors for the new generation of high-speed locomotives. |

|

2009 |

Specially designed wipers along with water sprinkling arrangement developed for three phase ABB locomotives. |

|

2012 |

First oil-free air compressor (RR 14100 OF) for the Indian Railways resulted in less maintenance, reduced CO2 emissions, and clean, oil-free air. These compressors are used in conventional electric locomotives. |

|

2014 |

Two-stage air-cooled, direct-coupled "common air compressor" (RR 20 100 CC) meant for all-electric locomotives. |

|

2015 |

15HP oil-lubricated compressor (RR15101) for the "Auxiliary Power Unit" application in conventional diesel and GM locomotives. |

|

2016 |

20HP oil-free compressors (RR20100 OF) for the WAG9 and WAP4 locomotives. |

|

2018 |

Underslung single-stage oil-lubricated DC motor-driven air compressor (U/S CRC 150). This compressor lifts the pantograph efficiently with a smaller footprint and is easy to mount on electrical multiple units (EMU). |

|

2017 |

Special pneumatic wipers for high-speed locomotives. |

|

2019 |

ELGi launched its oil-free range of air compressors (RR10100 OF / RR20100 OF) for the metro/electric multiple unit (EMU) segments. It bears a lighter construction tag with noiseless operation at less than 66 dbA. This oil-free piston series ensured reduced CO2 emissions and clean, oil-free air. It also enabled easy operations and reduced maintenance costs by up to 50% with improved maintenance schedules. |

ELGi and the Indian Railways is the story of a relationship that has withstood the test of time. We remain committed to addressing the Indian Railways’ compressed air requirements with customized compressed air solutions. And we will do so, not by resting on our past laurels but by continuously raising the bar.

References

- Wikipedia, Rail Transport in India

- The Indian Railways, 2020, An overview of the Indian Railways

- Press Information Bureau, 2020, the Indian Railways issues draft National Rail Plan

- Global Railway Review, 2020, Big data analytics for asset management in the Indian Railways

- Business Today, 2019, Centre Plans ₹ 50 Lakh Crore Investment In Railways By 2030

- Business Standard, 2019, Rs 3-trillion metro rail projects proposed for the next five years

- Financial Express, 2020, the Indian Railways to transform through technology

- The Hindu Business Line, 2020, How digitalisation is transforming the the Indian Railways

- Hindustan Times, 2021, the Indian Railwaysaims to become 'net zero carbon emitter' by 2030

- Railway Technology, 2020, Timeline: 165 years of history on the Indian Railways

- Times of India, 2012, Drought not a big calamity in India anymore

- National Bureau of Economic Research, 1975, Foreign Trade Regimes and Economic Development: India, Page 19

- Railways System for Analysis of Vidyut Energy, the Indian RailwaysWhistling Ahead Story of Growth & Modernization, Page 5

- The Compressed Air Journal, 2019, Safety first, for the Indian Railways