ELGi compressors reduce total cost of ownership

Anvar Jay Varadaraj, Head – Marketing & Communications interviews with Paresh Parmar from the Foundry Magazine

“As manufacturing regains momentum, we expect foundries and metals to expand their capacities or invest in green field projects. During this expansion, we believe customers should demand that their compressed air suppliers study their requirements to propose the more efficient compressed air solution,” says Anvar Jay Varadaraj, Head – Marketing & Communications, ELGi Equipments in an interview with Paresh Parmar.

The Tamil Nadu-based ELGi Equipments is one of leading air-compressor manufacturers in India and have announced their plans to become world No.2 position in the Global market by 2027. The company today offers a broad line of innovative and technologically superior compressed air systems. ELGi has earned worldwide distinction for designing sustainable solutions that help companies achieve their productivity goals and keep the cost of ownership low. ELGi offers a complete range of compressed air solutions from oil-lubricated and oil-free rotary screw compressors, oil-lubricated and oil-free reciprocating compressors and centrifugal compressors, to dryers, filters and downstream accessories. The company’s portfolio of over 400 products has found wide application across industries.

The company, also unveiled their new brand identity with a new logo and color scheme for its entire product range. Red and Black are more distinct and dynamic as compared to orange and grey. Red stands for performance, passion and energy. It reflects the drive to constantly evolve and keep getting better. Black is clear, bold and helps establish a distinct brand world. From the functional stand point, these colors add on to better visibility, consistency in execution and are unique in the industry. The air compressor market is growing steadily year on year. The market size is anticipated to be $20 billion in 2023, with 3.6% CAGR from 2016 to 2023.

The company has opted to take the innovation route to be World Number 2 in the global air compressor market by making the products energy efficient, oil free and with an increased uptime reliability. ELGi focuses on strengthening its attention on indigenous technology, research and development to innovate newer technologies in the air compressor industry.

Could you tell us the need for brand realignment?

Our old brand position of “Uptime” focused only on our service and neglected our products. The position also applied primarily to our Indian market, where customers were familiar with the ELGi brand. However, global aspirations require a global brand position. The “Always Better” brand position represents our product and service promise to our customers that will apply across all markets.

Could you elaborate on the latest trends in air compressors demand and the scenario in India – Opportunities & Challenges?

India will continue to be a strong market. Opportunities include: Energy efficiency: Customers are more aware of their air consumption and are demanding energy efficient solutions. This presents an opportunity for manufacturers to understand compressed air applications by industry and thus provide the most energy efficient solutions for customers. Energy efficient means the right sized compressor for the application and also exploring accessories like Variable Frequency Drives (VFDs) that can help save energy during fluctuating air demand. The challenge for manufacturers will be to invest time and resources in understanding customer applications. Air quality: Markets such as the USA and Europe demand better air quality, which means lower oil and water content. Better air quality results in better end products. Thus, products such as oil free compressors offer customers high quality of air with low service costs over the life of the compressor. Given that oil-free machines are more expense, the challenge for manufacturers is to convince customers of the air quality benefits and the lower cost of the lifecycle of the machine.

On your products and solutions for improving energy efficiency?

In terms of energy efficiency we have: Multiple Motor Classes: ELGi offers motors ranging from IE1 to IE4 efficiency for its compressed air range, which allows customers the option to pick the efficiency class as per their budget and requirements. Large Airends: Both our electric screw compressors, which are used in metal manufacturing and our portable screw compressors, which are used in mining, employ large Airends running at slow speed, which offer the best volumetric efficiency and consequently the lowest energy consumption in the industry. Variable Frequency Drives (VFDs): ELGi ’s screw compressors can be manufactured with in-built VFDs that will vary motor speed according to the air demand, thereby reducing power consumption. ELGi also offers standalone VFDs, which can be retrofitted to a non VFD compressor. Compressor Selection: Selecting the right sized compressor will save significant energy for the customer. Our sales engineers are trained in basic air audit techniques to help assess a customer’s demand pattern and propose the ideal compressor.

On the impact of your air compressors in reducing total cost of ownership.

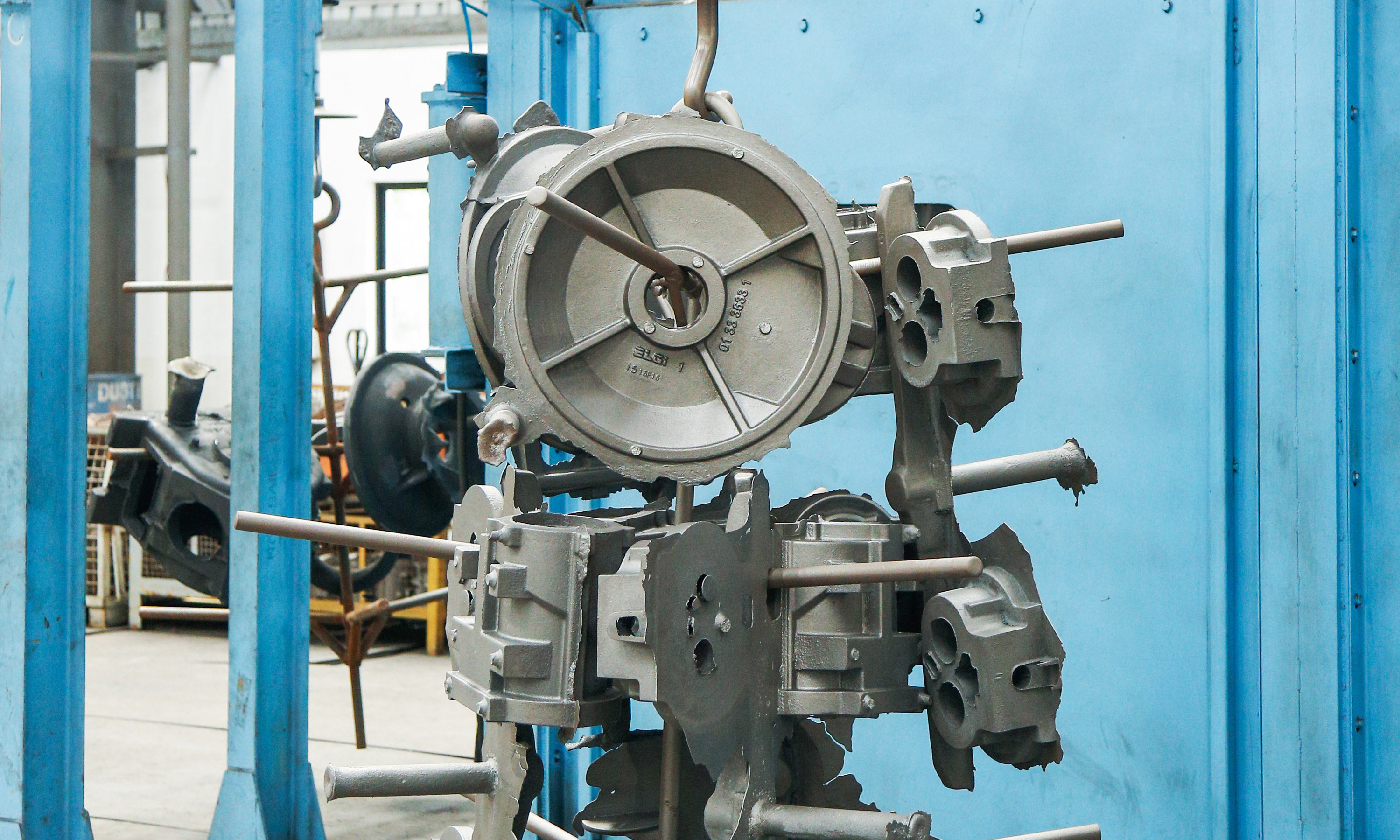

About 85% of a compressor’s cost derives from energy consumption, cost of spares, cost of service, warranty, and downtime. At ELGi, we believe in minimizing the impact of this 85%. With regard to parts and warranty, our manufacturing is highly vertically integrated. We have a captive foundry which supplies nearly 400 castings for our products. We have invested in machining centers to construct our Airends within a two micron tolerance. Both initiatives allow for the highest control over quality while offering the best warranty for customers. Our six year Airend warranty is the best in the industry and our Airend design allows for customers to service the Airend after ten years and continue running the machine as opposed to procuring a new machine or replacing the Airend, which will equal the cost of a new machine. Finally, our extensive service network in India helps minimize downtime or loss of production costs to the customers. In 98% percent of failures, ELGi has a track record of restoring air within six hours.

How do you see the shift in demand pattern from the end users for your air compressors from the metals and foundry industry?

As manufacturing regains momentum, we expect foundries and metals to expand their capacities or invest in green field projects. During this expansion, we believe customers should demand that their compressed air suppliers study their requirements to propose the more efficient compressed air solution.

Foundries face difficulties due to lack of skill sets in analysing plant demand for compressed air. Please comment.

The responsibility lies with the compressor suppliers. At ELGi, we believe that we are responsible for understanding our customers’ applications sufficiently well to propose energy efficient solutions. Thus, customers should demand expertise and not thus machines from their suppliers.

Could you tell us how important it is to install energy efficient equipment in order to remain competitive globally?

Often, companies compromise on the quality of their equipment for a lower entry price. For those industries, where compressed air usage is high and energy is expensive, managers should adopt a lifecycle cost analysis as opposed to just focusing on the price.

Poor demand analysis and absence of high dust filtration capacity are a major problems today. How do you address this?

There are two elements to this. Customers should demand expertise from their compressor suppliers to better understand their air demand and thus select the right machine. With regard to wastage, ELGi provides complimentary air audit services to our customers to understand the areas of leakage and the cost to rectify. Over the past year, ELGi has identified nearly Rs. 60 Cr. In annual energy savings across 40 customers. As second element, customers should be willing to invest in improving the quality of their infrastructure. For example, ELGi’s foundry floors are maintained to the cleanliness standards of a hospital floor. The cleanliness standard ultimately results in better quality products.

How do you see the foundry market improving vis-à-vis the acceptance for your air compressors? We have invested in understanding the foundry industry’s usage of compressed air. We have a good understanding of variations in air demand and the potential savings. Thus, we are able to have intelligent conversations with customers about the best possible compressed air solution for their application. We believe such expertise will allow us to build trust and long term relationships.

How do you see the competition in the market air compressors?

Competitors such as Atlas Copco and Kaeser provide high quality solutions with European pedigree. While we will focus on competing with the best technology and efficiency solutions, we believe we can differentiate ourselves by understanding our customers’ air applications and thus differentiate ourselves by being the most customer centric supplier.

On your R&D efforts.

We invest significantly into our technology roadmap. The focus includes improving the efficiency of current compressor technology, but also on the air compressor of the future. Specifically, we are focusing on commercializing innovative oil-free compressor technology that matches the cost and efficiency of oil-lubricated compressor technology.

On bringing latest technologies to India.

Given that India is our largest market, we will prioritise such technology for India. ELGi’s commitment to our customers is to be always better with our products and services. We would appreciate the opportunity to showcase our products and service to new customers.

How do you see the industry going forward?

We are cautious on the short term (one year) as we are seeing signs of growth. We are positive for the medium term as metals and mining are input industries to other industries.

This article originally appeared on the Foundry Magazine.